Description

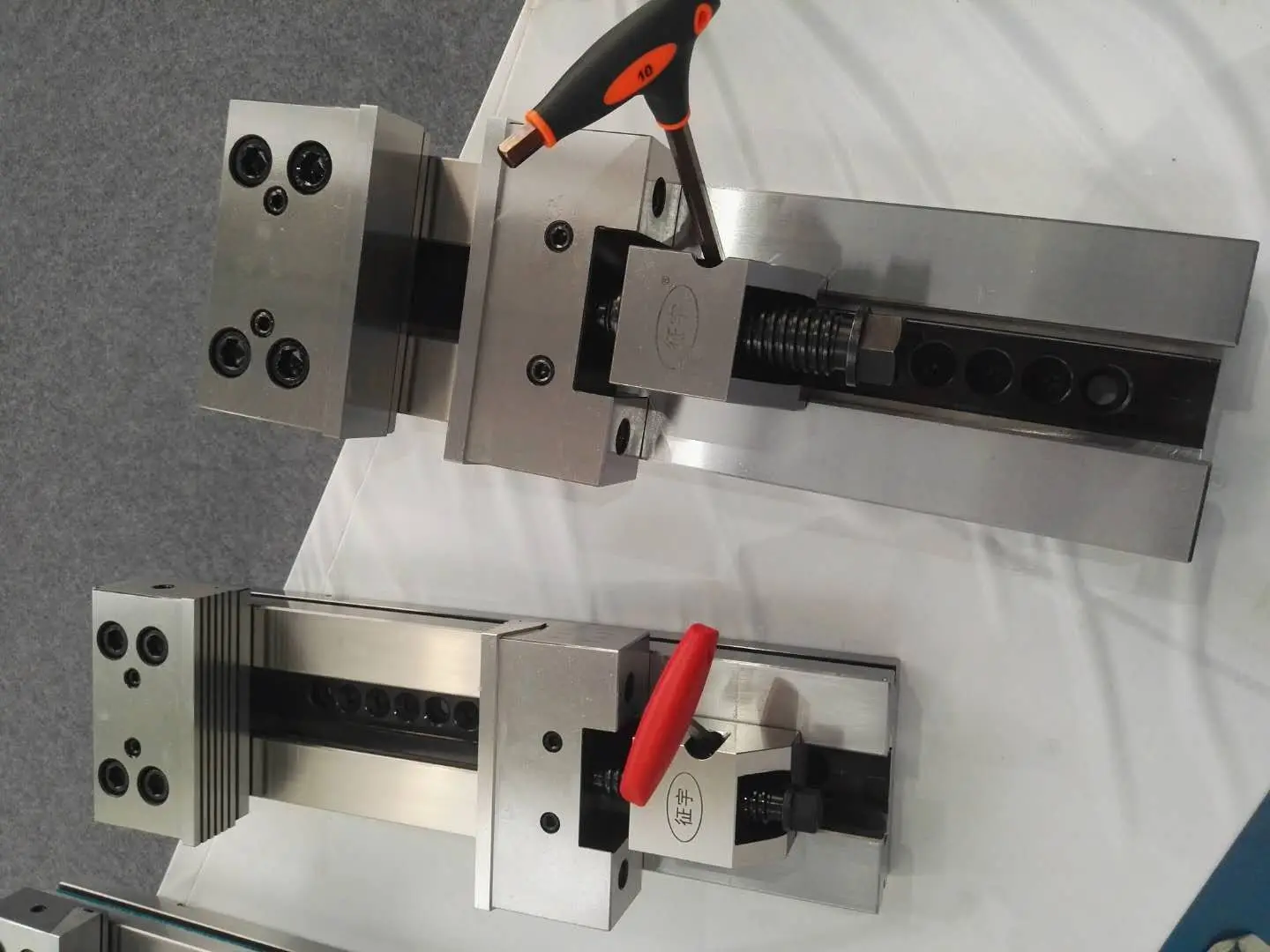

1.Choose the right vise and fix it on the workbench.

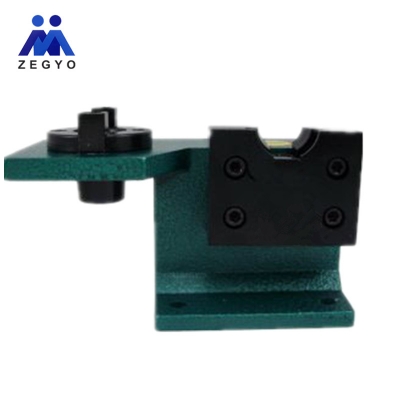

2.Unscrew Inner hex-angular screw cap wire(16) to make the supporting seat(7) move freely.

3.Move the supporting seat(16) according to the target size. Fix the steel ball(17) to the suited hole of vise’s main body(15)

4.Tighten the inner hex-angular screw of supporting seat to fix it.

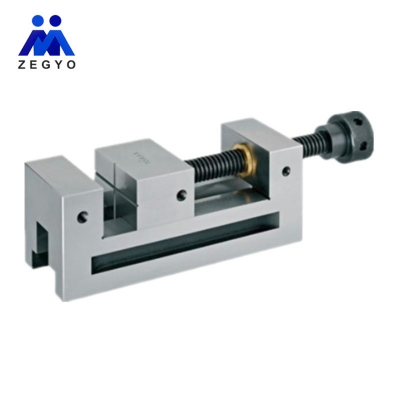

5.Use socket spanner to rotate lead screw(8) in order to move movable jaw block(6) for the purpose of tightening and loosening.

6.Above-mentioned instructions are applicable to all sorts of product designs.1.Choose the right vise and fix it on the workbench. 2.Unscrew Inner hex-angular screw cap wire(16) to make the supporting seat(7) move freely. 3.Move the supporting seat(16) according to the target size. Fix the steel ball(17) to the suited hole of vise’s main body(15) 4.Tighten the inner hex-angular screw of supporting seat to fix it. 5.Use socket spanner to rotate lead screw(8) in order to move movable jaw block(6) for the purpose of tightening and loosening.

1.This are precision Modular Vises. It should be used on the machine platen with high plane level ≤0.005mm. 2.Please use trapezoidal pressing plate to fix the vise. It’s forbidden to use the screw hole of vise to fix it. 3.Maintenance: Be sure to frequently inject lubricating oil for easily worn parts. Please remove iron and take anti-rust measures after use. It’s forbidden to move jaw and lead screw with iron. Beware of causing damage to vises to avoid reducing service life.

4.Please take anti-rust measures and pack in plastic box if don’t use often.

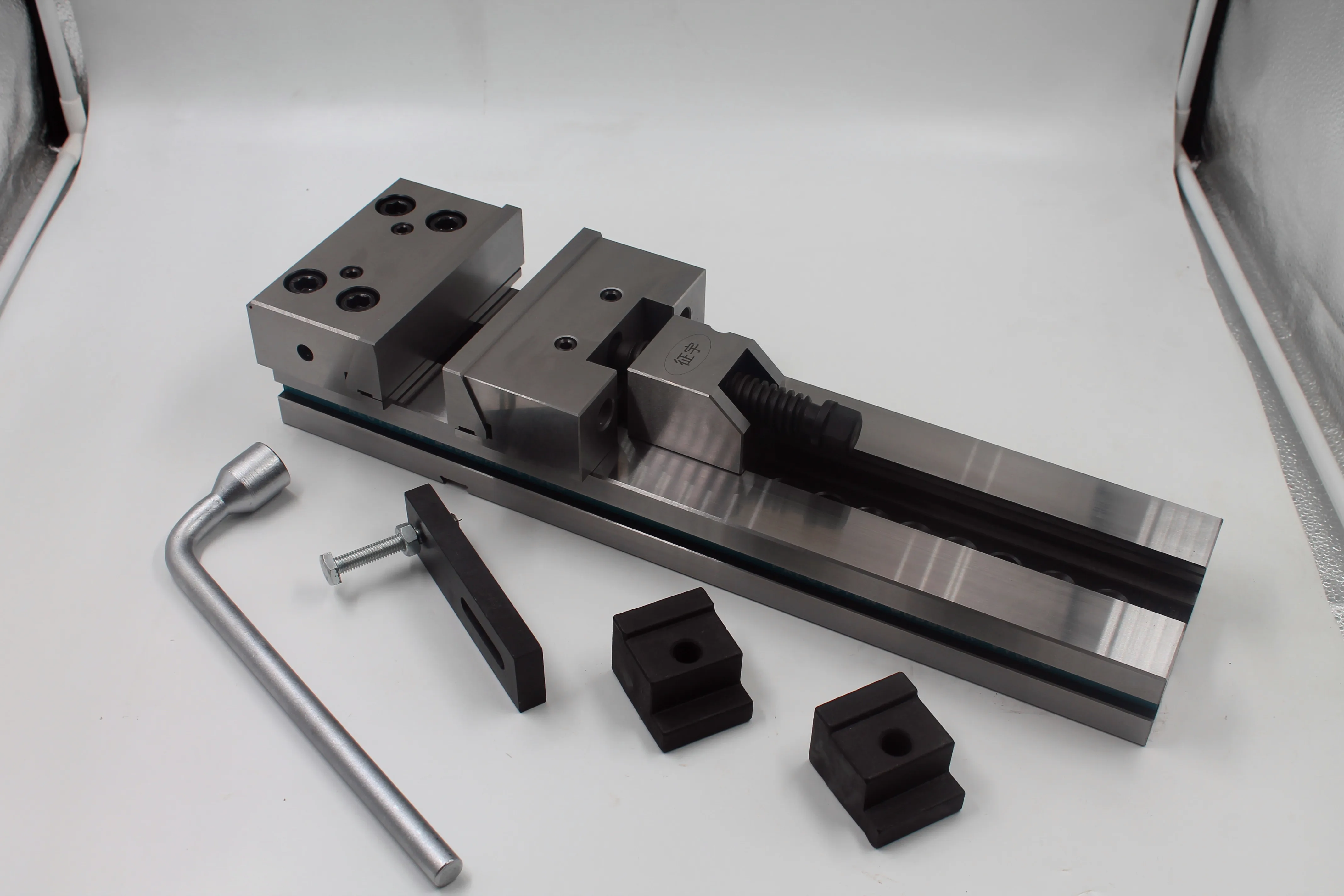

Detailed Images

| File Name : | Format: | Size: | Download: |

|---|